Metal mold

- Home

- Metal mold

Do you have any worries about molds? I am available for consultation.

Do you have any of these problems with molds? Please let us know your story and situation.

- No blueprints or data.

- I don’t know what kind of manufacturing method (construction method) is the best choice.

- The supply of products is unstable, and we would like to consider a new customer.

- We consulted with other companies, but could not come to an agreement in terms of quality and cost.

Maintenance is OK even for products made by other companies! If the actual product is available, it can be reproduced and modified without drawing.

We also provide maintenance services for molds manufactured by other companies. Also, don’t worry if you don’t have product drawings or mold drawings.

It is possible to make a mold if you have the actual item. We 3D scan the product, create a 3D model of the product, and modify the mold based on it.

Wisdom for total cost reduction gained from numerous achievements

As the number of achievements is large, the range of support is wide, so it is possible to support all kinds of products.

We have the experience and knowledge to achieve total cost reductions for each product, so please let us know what you can do.

One-stop arrangement possible

- Cutting products/prototypes

- sand casting products

- die casting products

- plastic products

- press products

- others

Peace of mind with long-life mold design

In addition to preventing production stoppages due to mold structure due to frequent breakage, we also improve yields and design molds that are easy to cast and have a long life, in order to reduce costs.

High-quality mold manufacturing that can be achieved in a short period of time

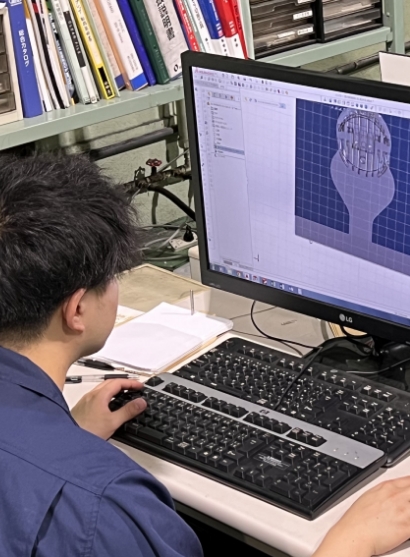

The mold factory has a design room in the manufacturing process.

From the initial stage of design through the manufacturing process to the final stage, we aim to shorten the lead time and manufacture high-quality molds in a short period of time by having thorough discussions between the designer and each manufacturing staff. It has come true.

Proposing the best method to always cast the best product

The primary mission in mold manufacturing is to maintain stable casting over the long term.

The quality of the mold is greatly influenced by the hot water circulation plan.

By accurately predicting the flow of molten metal and the solidification state during casting, we propose the optimal method for always casting the best product with a low product defect rate.

Equipment list

| Owned equipment | Maker | model | Number |

| Machining | Makino | V56i | 1 |

| OKK | MCV560 | 1 | |

| OKK | GR400 | 1 | |

| wire electric discharge machine |

Sodick | AQ327L | 1 |

| Die-sinker EDM |

Sodick | AG75L | 1 |

| General purpose milling cutter |

Makino | AE85 | 1 |

| YAMASAKI | YZ-320NCR | 1 | |

| Polishing machine | HITACHI | GHL-B506NS | 1 |

| Radial drilling machine |

OGAWA | HOR-1600 | 1 |

| Kira Iron Works | KU-40 | 1 |